|

| POWDER

TRANSFER SYSTEM |

|

For Vacuum Transfer of Powders,

Granules, Sugar, Tablets and Pellets in Pharma and Food Industries

Applications:

For charging of RMG, Sifter, Mill, Mixer, Blender, Bin, Tablet Press

or any other such equipment

Key Features:

- Can be used for transfer of products having bulk densities upto

1.0gm/cc

- Total Discharge no Retention

- No segregation or degradation of Product

- No tool required for opening & cleaning

- Available in three sizes for upto 300, 600 & 1200 kg/hr, depending

on bulk density and nature of product

- Compact design, complying with current international gmp norms

- Universal adaptability can be easily installed on any receiving

equipment like process tank, ibc, conical mill,pin mill, blender,

tablet press etc.

- Adaptors provided to suit existing inter opening on user's equipment

- Economical and easy to install and operate

- All contact parts made of ss304 / ss316 / ss316l and Pharma

grade gaskets / seals

- No use of oil or grease in any of the contact parts

- Mobile trolley mounted version also available

- All validation documents like dq/iq/oq are supplied with the

system

WE ARE THE PIONEERS IN DESIGN & SUPPLY

OF BULK SUGAR / POWDER TRANSFER SYSTEMS TO PHARMA / BULK DRUG /

FOOD / CHEMICALS INDUSTRIES

|

|

|

| CRYST

MILL / CONICAL MILL |

| Applications:

For Granulation, Sizing, Milling in Pharmaceutical, Bulk Drug, Food,

Cosemetic, Chemical Industries, etc.

Key Features:

- Hygienic and compact design complying with current international

GMP norms

- All contact parts made of SS304 / SS316 / SS316L and Pharma

grade gaskets / seals

- Sieve can be removed and replaced in less than 30 seconds

- Operational Interlocks for operator safety

- Variable Speed Drive for flexibility in having desired results

with a wide range of productsc

- Capacities upto 1000 kg/hr depending on product bulk density

and other properties

- Tool free maintenance - opening, cleaning and changing of screen

does not require any tools and can be done in less than 5 minutes

- Sieves ranging from 0.25mm to 25mm can be used to achieve various

degrees of capacities, granulation and sizing

- No heating of product during granulation / sizing operation,

due to better air circulation and lesser impact action.

- Also available with VFD for achieving desired particle size

v/s screen size

|

|

|

| SIFTING

& SIZING EQUIPMENTS |

|

Applications:

For size reduction and milling of products to very fine powders

down to 10 microns

Key Features:

- Robust construction with SS304 / SS316 / SS316L contact parts

- Capacities upto 1000 kg/hr depending on product bulk density

and other properties

- Easy and rapid cleaning as per current International GMP requirements

- Tool free maintenance - opening, cleaning and changing of screen

does not require any tools and can be done in less than 5 minutes

- Can be supplied with integral Powder Charging System

- Also available with VFD for achieving desired particle size

v/s screen size

|

|

|

| INTERMEDIATE

BATCH CONTAINER (IBC) |

| |

|

Applications:

For intermediate storage, formulation, blending and handling of

products before, between and after various processes.

Key Features:

- Designed with current international GMP guidelines - Without

any nooks and corners for easy cleaning

- Mirror finish from inside and adequate hopper angle for easy

and complete discharge of products

- Contact parts made of SS304 / SS316 / SS316L and Pharma grade

gaskets / seals

- Universal bin handling and stacking system for easy automated

handling and stacking of bins

- Optionally available with castor wheels and wheel locking arrangement

- Matt finish and ground weld joints on outside with circular

legs and frame without sharp corners to avoid water stagnation

during washing

- Butterfly valve provided at bottom discharge

- HDPE / Nylon pads at leg bottom

- Numbering and Bin Weight indication provided on every bin

|

|

|

|

|

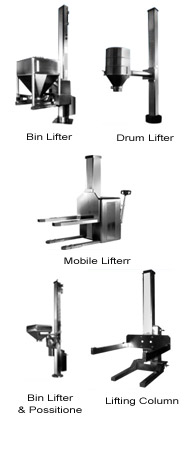

| LIFTING

AND TILTING DEVICES |

|

Applications:

For easy lifting and tilting of FBD bowl

Key Features:

- Fully automatic system, with hydraulic lifting and tipping arrangement

for quick and easy handling

- Eliminates tedious and unhygienic manual handling of products.

- Quick fixing lever clamp provided on the cone to clamp FBD bowl

with the system

- Available in standard capacities of 60kg, 100kg, 200kg, and

300kg.

|

|

|

| MAGNETIC

CROWN ELEVATOR |

|

Applications:

For efficient elevating and loading of bottle crowns into the filler

machine in soft drink /beverage plants

Key Features:

- Continuous flow of crowns to the filler machine hoppers, resulting

in an increase in bottling efficiency by 7 to 10%

- Reduces uncrowned bottles.

- No relative motion between the crowns, thus preventing rubbing

and hence rusting of crowns

- Eliminates manual handling of crowns - increases hygienic standards

- Level sensor logic provided

|

|

|

| CAP

TRANSFER SYSTEM (CAP BLOWER) |

|

Applications:

For efficient transfer and loading of caps to Filler Machine hopper

in Soft Drink / Beverage / Mineral Water / Pharma / Food Industries

Key Features:

- Compact design with stainless steel construction

- Built-in bowler and control panel

- UV radiation source provided for getting caps free of germs

- Permits easy loading of caps from cartons to filler machine

hopper

- Automatic delivery of caps to the filling machine on demand

- Air suction filter provided to protects the caps from dust /

impurities

- Level sensor logic provided

|

|

|

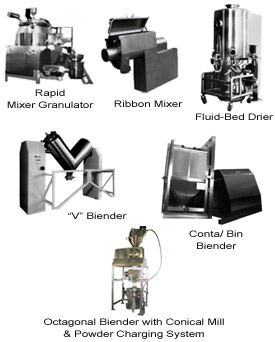

| MIXER

& BLENDER |

|

Applications:

For uniform and efficient blending / mixing of ingredients

Key Features:

- Elegant design with matt finish from outside and mirror finish

from inside

- Blender cones and discharge valves are carefully designed &

gas purging facility provided for full discharge of materials

- Carefully designed and fully removable baffle for efficient

and fast blending without damage to powders / granules & easy

cleaning

- Contact parts made of SS316, and Pharma grade gaskets / seals

- Integrated Powder Charging System provided, for quick and automatic

charging of blender, without manual handling.

|

|

|

| PLANTS |

|

Applications:

For prevention of dusting in plants by trapping of dust at various

dust generation sources and collecting the dust at a centralized

location

Key Features:

- Compact and efficient hood design to suit the esthetics of the

plant interiors

- No setting of dust in the ducts

- Facility for easy and quick cleaning of ducts

- Automatic pulse-jet of filter bags

- Complete system layout done to suit user's existing plant &

equipment

|

|

|

| ROLL

COMPACTOR |

|

Some powder raw materials have the

characteristics of low density (low specific gravity) and bad flow

ability. By using the Roll Compactor – dry granulation process,

it will improve the above characteristics and result in bigger bulk

density, higher specific gravity, good flow ability which improves

and simplifies the dry process granulation.

Applications:

Pharmaceuticals:

Free flowing granules for automatic packaging

Compact granules to reduce package size.

Dust free granules to facilitate handling

Granules can be filled in smaller capsules

Granules for tabletting

Food

Industry :

Granules for compressed candies, chocolate, dairy products, seasoning

etc.

Chemical

Industry :

Catalyst, Fertilizers, pesticides, dyes, cosmetics and other chemicals.

Key

Features:

Roll compactor

is mainly used for dry granulation.

The advantages of the dry granulation machine are :

The Roll Compactor is designed to have 3 functions in one unit.

These are compression, granulating and sifting. It is simpler operation

than wet granulation.

The Roll Compactor also enables to stabilise mixtures of powders

and ensures an easier packaging, handling, storage and transportation

of powders.

We have developed a wide range of compactors are user friendly and

are specifically adapted to as per the requirements of the pharmaceutical

industry; online production without dust generation, production

area fully isolated from the drive system, quick and easy changeover

parts in the production area and easy cleaning of these parts.

The PLC Based control system controls and monitors the compaction

and granulation process with full instrumentation and data acquisition

capabilities.

The design and construction of the Roll compactor is according to

the current GMP.

No water or other liquid is added, so the loss of active ingredients

due to decomposition can be eliminated. Highly stable granules can

be obtained.

Feeding Hopper can move up and down by the inbuilt hydraulic system

for ease of maintenance and cleaning.

The VFD drive backed with hydraulic system is provided for charging

the screw, the roller speed and the roller pressure for precise

and variable adjustment with respect to the product's characteristics.

The pressure of hydraulic system is adjustable to accommodate a

wide range of materials.

The cooling system reduces high temperature generated during the

operation that maintains the product quality.

High percentage of usable granules can be achieved by the better-designed

breaking blades and crushing rollers.

Option 'A' - Online sifter is provided to segregate granules and

fines

Option 'B' - A automatic vacuum transfer conveyor is provided to

transfer the fine powder back to the compactor as a recycle powder

which will give better yield and granules.

|

|

|

OTHER

PRODUCTS |

|

- Fully Automatic Mixers, RMG, Ribbon Blenders, V-Blenders, Bin

Blenders

- Fluid Bed Driers / Processors / Granulators with Loading / Unloading

Systems

- Automatic Cleaning and Drying Systems, De-contamination Systems

- Dust Collectors, Bagfilters

- Rotary Valves, Screw Feeders, Wet Mass Shredders

- Vibro-Sifters, Air-Swept Sifters, Self-loading Sieves

- Divertor Valves, Flap Valves, Magnetic Separators

- Silos, Bins, Weigh Hoppers

- Pneumatic Conveying Systems and Mechanical Conveyors

- Complete Systems and Plants for Pharmaceutical, Chemical, Food,

Beverages, Petrochemicals, Pulp and Paper Industries

- De-dusting, De-stoning, Pneumatic Conveying and packing Systems

for grains and pulses ¨ Turn-key Projects in Powder Handling and

Processing

- Special Purpose Machines and Custom-built Equipment.

|

|

|

|

|